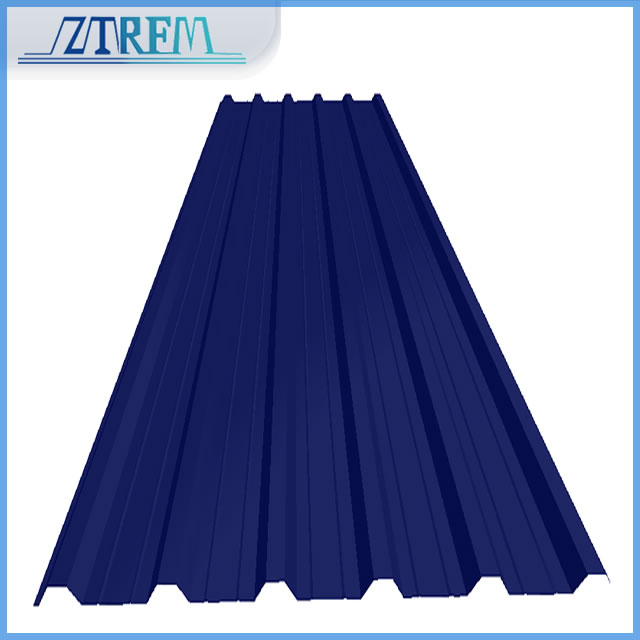

Anti-corrosion and heat insulation metal roofing tiles

Anti dripping felt roofing sheets , where to use:

It will be used in the warehouse for protect the goods against moisture.

It will be used on farm to protect the livestock, for example when cold water drops on the hen, it will not lay eggs. If cold water on cattle, sacred cattle will not long meat.

Anti-corrosion and heat insulation metal roofing tiles

Anti-corrosion and heat insulation metal roofing tiles is designed for updating and improving workshop situation. The reflection coefficient of Zhongtuo mirror silver light is as high as 81%, which can effectively reflect light and heat. At the same time, the composite material has an extremely low thermal conductivity, as low as 2.93W/m.k, while the thermal conductivity of the color steel tile plate is 41W/m.k. Benefiting from these two properties, Bishi has excellent thermal insulation properties. Compared with the same period of last year, the standard factory building of color steel tile can cool more than 8 degrees in high temperature weather.

In order to better deal with the production environment of steel plants, Zhongtuo has specially developed metallurgical anti-corrosion and heat insulation panels, which have better anti-corrosion performance and longer service life. Anti-corrosion board is mainly used for wall materials in steel plants. The thickness of the board is 0.6mm. The recommended profile specification is 820 or other versions. We can design according to the customer's version.

Anti-corrosion board is mainly used for roofing materials of steel plants. The thickness of the board is 0.8mm. The recommended profile specification is 760 or other versions. We can design according to the customer's version.

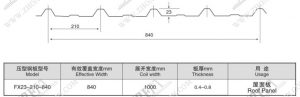

Drawing profile for your reference:

Where and who needs to choose or update Anti-corrosion and heat insulation metal roofing tiles?

High temperature season, cost a lot of cooling costs

In the hot season, many factories have to spend a lot of heatstroke prevention and cooling costs to ensure the production environment and ensure production efficiency. For many large industrial workshops, there is no way to install air-conditioning and other cooling measures in the workshop. Therefore, many factories can only adjust their work and rest time during the summer hot season. For example, they start work at 5 am and leave work at 10 am. This reduces the overall production efficiency, and even the production quality cannot be guaranteed. For the warehouse industry, high temperature will significantly shorten the shelf life of stored goods, such as grain, and must be insulated and cooled.

Experimental comparison data:

1.Step one, we put the sulfuric acid on those three different types coil to test the Corrosion resistance.

2.Wait 2 minutes later and then we check the surface of the coil.

So it is easy to see the different.

Customer cases for sharing:

Customer: The roof of the customer's factory made of colored steel tiles has rusted and leaked very seriously in less than 3 years. Because the workshop produces a lot of corrosive gases, the requirements for acid and alkali resistance and corrosion resistance of the workshop are particularly high. It must be done again. I checked a lot of materials and communicated with many friends, but I didn’t meet the ideal materials.

Solution: Zhongtuo Anti-corrosion and heat insulation metal roofing tiles. First of all, acid and alkali resistance is the most important. Other brand products, including Baosteel, dare not say that they can be used normally in acid and alkali corrosive environments like ours. Insulation is also very important to us, because we cannot produce at all during the high temperature season in summer, and workers will suffer heatstroke. We can only adjust our work and rest time, go to work at 5 o'clock in the morning and leave work at 10 o'clock in the morning, which is inefficient.

Questions: How long can your products last? Will it break after 2-3 years? Can you Anti-corrosion and heat insulation metal roofing tiles be used around 10 years?

Answer: Yes. Zhongtuo anticorrosive tile, a new generation of roofing and wall materials, perfectly solves the different defects of the current roofing materials of various factories, conforms to the country's encouragement of new environmental protection materials, and can be widely used in roofs and walls of factories, warehouses, etc. Durability, heat insulation, anti-corrosion, noise reduction, etc., better solve the problem of factory adjustments due to high temperature, give workers a more comfortable environment, improve work efficiency, and have a shelf life of up to 10 years.

Related product you may need: Special anti-rust screw:

The special anti-rust screw is a special anti-rust screw specially developed for anti-corrosion and heat insulation tiles. The anti-corrosion and heat-insulation tile is matched with the special anti-rust screw of Bishi, which can prevent rust and corrosion more comprehensively, and comprehensively strengthen the service life of the house and wall of the factory. It is an ideal building material for all kinds of steel structure workshops.

Reasons why you need to choose anti-rust screw together with roofing tiles?

Anti-corrosion insulation tile is durable, does not rust and leak, and can be used for more than 10 years in corrosive environments. However, during the promotion of anti-corrosion and thermal insulation tiles, we found that there is bad combination of anti-rust screws on the market. For plant owners and users, if there is no problem with tiles, but the common screws used are corroded, it is also a serious quality hazard. Therefore, Zhongtuo has specially researched the anti-corrosion technology of metal screws, discussed with experts in the metal material and surface treatment industry, and jointly researched and developed with experts in the screw industry, and finally formulated the material, structure and technology of the special anti-rust screw.

Features:

The special anti-rust screw adopts hexagonal plate washer tail screw structure, diameter 5.5mm, carbon steel material, the screw body is treated with Dacromet, with 3 04 stainless steel + EPDM gasket.

- Super corrosion resistance: The thickness of Dacromet film is only 4-8μm, but its anti-rust effect is more than 7-10 times that of traditional elector-galvanizing, hot-dip galvanizing or paint coating. Bisida Crowe treatment adopts 4-bake 4-coating process, and no red rust appears in the salt spray test for more than 1000h.

- No hydrogen embrittlement: Dacromet's processing technology determines that Dacromet has no hydrogen embrittlement phenomenon, so Dacromet is very suitable for the coating of stressed parts.

- High heat resistance: Dacromet can withstand high temperature corrosion, and the heat resistance temperature can reach above 300℃. The traditional galvanizing process is scrapped when the temperature reaches 100°C.

Therefore, the special anti-rust screw of we using this technology has strong anti-rust and corrosion resistance, and is suitable for use in various corrosive environments, which greatly reduces roof repair and maintenance costs. At the same time, this treatment has no pollution during the whole coating process, which is a kind of green environmental protection technology.

In order to better protect the contact part of the screw drilling, the special anti-rust screw of Zhongtuo adopts a gasket composed of a 304 stainless steel metal sheet and an EPDM rubber gasket. It is well known that 304 stainless steel has excellent corrosion resistance. EPDM rubber, also known as EPDM rubber, is a copolymer of ethylene, propylene and a small amount of non-conjugated diene. It is represented by EPDM (Ethylene Propylene Diene Monomer) because its main chain is composed of chemically stable saturated hydrocarbons. It contains unsaturated double bonds in the side chain, so it has excellent aging resistance such as ozone resistance, heat resistance, weather resistance, etc. It is widely used in automobile parts, construction waterproof materials, wire and cable sheaths, heat-resistant hoses, tapes, and automobile seals And other fields. In the Bishi anti-rust screw structure, the EPDM rubber gasket is under the 304 stainless steel metal sheet, with a larger contact area, dispersing the pressure of the screw, and at the same time using its own elasticity to protect the screw and prevent loosening. Due to its excellent weather resistance and anti-corrosion performance, this structure will not aging and fail over time, nor will it rust and fail. The gasket made up of 304 stainless steel and EPDM has become the best material for the rust and corrosion protection of Bisch special screws.

We also have another types roofing sheet:

32/1000 Box Profile PE or Aluminum foil Coated Roof Sheet

Noise reduction and condensation effect reduction metal roofing sheet

Three layers composite heat insulated metal roofing and cladding sheets