Anti dripping felt roofing sheet rolling forming machine

Anti dripping felt roofing sheet is pre-applied to our PBR, Imperial Rib and Retro R metal panels. Can hold moisture within its felt membrane. Once the temperature recedes back below dew point, it releases moisture back into the air in the form of normal humidity.

Anti dripping felt roofing sheet rolling forming machine is designed to make the both PPGI roofing sheets and PPGI roofing sheets with felt fully automatically in batch.

Anti dripping felt roofing sheet rolling forming machine is designed to make the both PPGI roofing sheets and PPGI roofing sheets with felt fully automatically in batch. In the following part, let us take random drawing to show how the machine designed:

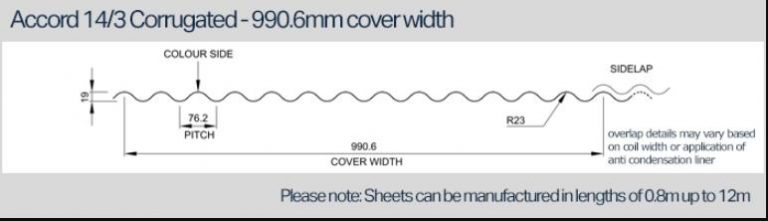

3" Corrugated Steel Sheets (14/3) 990.6mm Cover

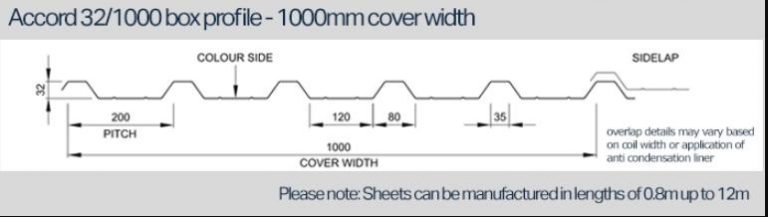

32/1000 Box Profile

Anti dripping felt roofing sheet rolling forming machine, same like other metal roofing sheet rolling machine, we can design either to be single layer or double layer roofing sheet machine. Here we take the double later as an example:

Anti dripping felt roofing sheet rolling forming machine Basic parameters and elements for your reference:

5 tons automatic hydraulic decoiler

Hydraulic system is used to be the power of open and closure of segments. The speed sensor of the decoiler enables the decoiler to automatically adjust the speed to match up the roll forming machine. And the automatic loading cart will improve the working efficiency and save the labor cost.

Carrying capacity: 5 t Max

Coil width: 1250mm

Coil inner diameter: 450-550mm Hydraulic segment expansion Electric motor transmission

Hydraulic motor power: 4kw

Entry Beach with felt coating device:

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee the products are neat, parallel and uniformity.

Add: Include pre manual cutting device and anti- dripping felt coating device.

Roll Forming System:

Dimension: about 10000 mm х 1850 mm х 1500 mm Weight of main part: 8.5 tons

Voltage: 380 v 50 hz 3 phase or customized

Roller fixer: middle plate 20mm

Frame: 400 H steel welded

Drive mode: Chain (double)

Material of rollers: 45# steel with surface hard chromium plating (electroplate spacers)

Material of shafts: 45# steel with quench treatment Diameter of shafts: φ 85 mm

Number of rollers: 19 rollers + 20 rollers Main drive motor power: 7.5 kw

Material thickness: 0.3-0.8 mm Working speed: 0-20 m per minute

This machine contains a yellow color safety cover:

Shearing Mechanism:

Material of blades: Cr12 quenched Power supply: Hydraulic power

Double pillar frame, more stable

Products Receiving Table: fully automatic stacker, you can choose 6 meters or 12 meters:

It is installed in the exit of the roll forming machine, it can cooperate with the cutting, the roof sheet before cutting are supported by the plate, after cutting, the finished products will automatically drop down to the stacking area, when the stacking quantity reaches, operator can press the button which enables the finished products automatically moving to packing area aside, so that the rest of things can be taken care of.

The main motor power: 2.2 kw Receiving table length: 6000 mm

The max height of ready products: 300 mm Work flow: feeding-dropping-stacking-move out

Storage table is controlled by the motor, can remove the products from one side to another side.

How to adjust Anti dripping felt roofing sheet rolling forming machine when with felt and without felt?

Zhongtuo Anti dripping felt roofing sheet rolling forming machine is design to produce both type with felt and without metal roofing sheet, then how to adjust the space of the shaft and roller thickness. For this type machine, one the left side we will design some handrail, when rolling sheet without felt, you need to lower down.

When handling sheet with felt, simple make the handrail up, that is quite easily.

As to the shearing part, it is also adjustable with sensor.

Anti dripping felt roofing sheet rolling forming machine-double layer roofing sheet machine working videos for your reference:

Why and when you need to choose Anti dripping felt roofing sheet rolling forming machine?

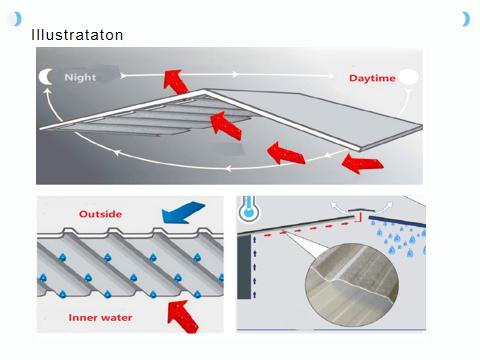

When temperature and humidity conditions reach dew point, moisture can condense on the underside of metal roofing and potentially cause water damage to the inside of your building.

Anti dripping felt roofing sheet is pre-applied to our PBR, Imperial Rib and Retro R metal panels. Can hold moisture within its felt membrane. Once the temperature recedes back below dew point, it releases moisture back into the air in the form of normal humidity.

Anti dripping felt roofing sheet rolling forming machine FEATURES:

- Customized machine, we can design the metal roofing sheets in the shape and sizes of PBR, Imperial Rib and other products

- The Anti dripping felt roofing sheet rolling forming machinewe can give 10-year warranty.

- More types film and felt like for flame spread and smoke generation for insurance specifications are optional.

- Cost saving: up to 25% versus traditional solutions

- Durability – The Anti dripping felt roofing sheetisn’t susceptible to ripping, tearing or deterioration like standard insulation and vapor barriers

- Easy to clean and maintainness

- Reduced labor – no need to roll a vapor barrier down over purlins then seal with tape

- Approved for use in animal confinement

- Reduces exterior noise

Anti dripping felt roofing sheets , where to use:

- It will be used in the warehouse for protect the goods against moisture.

- It will be used on farm to protect the livestock, for example when cold water drops on the hen, it will not lay eggs. If cold water on cattle, sacred cattle will not long meat.