Anti-aging Corrugated Sheet rolling forming Machine

Anti-aging Corrugated Sheet rolling forming Machine typically includes the following components.

- Manual decoiler

- Feeding guide

- Roll forming system

- Transmission system

- Hydraulic system

- Control system

- Hydraulic cutter

- Oil pump

- Runout tables

While in some other cases, we can provide hydraulic decoiler and auto stacker as per request.

Our roofing sheet roll forming machine have muti-function,not only can produce normal PPGI and color steel material,also can use for composite material.

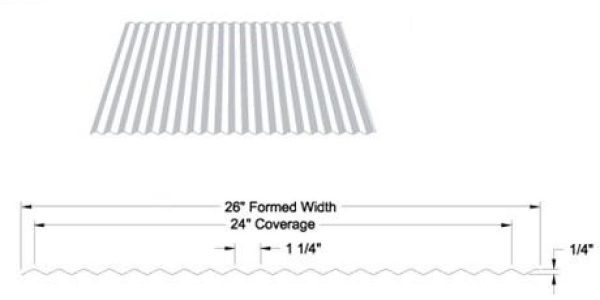

Take the following corrugated sheet drawing for example:

Based on the corrugated sheet dawing and customer needs, now we have three optionsfor you to choose:

Option A: normal speed 25 meter per minute corrugated sheet machine.

Option B: Higher speed 35 meter per minute corrugated sheet machine

Option C: Fast speed 50 meter per minute corrugated sheet machine

In this article, I only show option A, please check other options in next article.

Technical Parameters of the Anti-aging Corrugated Sheet rolling forming Machine:

Individual forming stands Anti-aging Corrugated Sheet rolling forming Machine

- Raw Material: Prepainted color steel coils; Galvanized steel coils; Galvalume steel coils;

- Yield strength: 235MPA-550MPA;

- Raw Material Thickness: 0.3-0.8mm;

- Raw Material Width:914-1250mm;

- Main Power: 5.5 KW;

- Forming stations: 16-22 stations;

- Stands structure: Conjoint type OR Individual Type

- Machine Frame stand: 36# H Beam steel welded

- Thickness of Steel Frame: 18mm

- Material of Roller: High grade 45# steel, Polished and coated with 0.05mm hard chrome.

- Shaft Material: High grade 45# steel

- Diameter of shafts: 70mm

- Hydraulic Cutter: Stop to cut

- Material of cutting dies: Cr12 steel

- Hydraulic power for cutting: 4KW

- Cutting lengths and quantities: Clients can set required lengths and quantities through the touch screen on PLC control box.

- Control system: Panasonic PLC, Inverter, CHNT transformer and Omron encoder

Where the Anti-aging Corrugated Sheet rolling forming Machine is used?

Anti-aging Corrugated Sheet rolling forming Machine is metal roll forming equipment that produces Anti-aging corrugated Metal Roofing and Siding Panels. In our daily life we can see many fans of corrugated metal sheets.

It either could be used as roofing or it can be used as cladding.